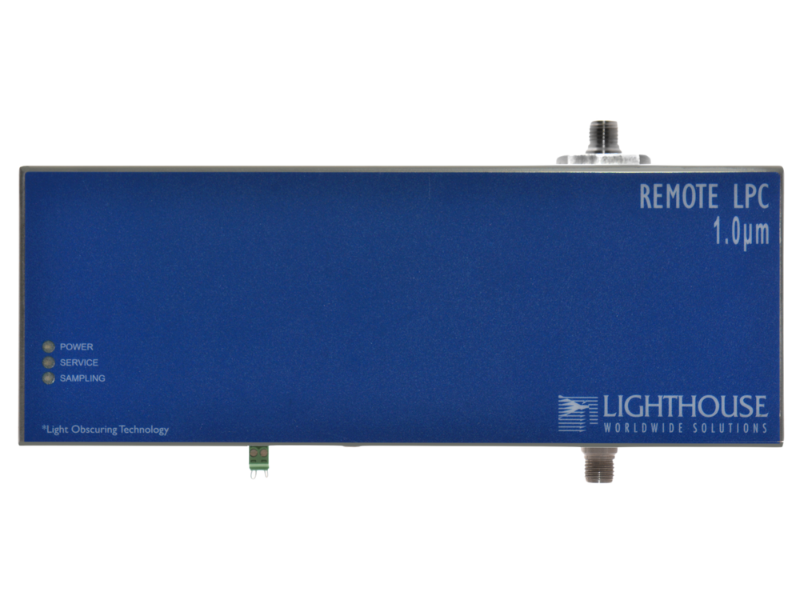

LPC Remotes will provide you the continuous monitoring data you are looking for. Our remote liquid particle counters will help you determine the DI water being supplied to your process always maintains a certain level of cleanliness. These units can be easily setup into facility monitoring systems and can also be easily cleaned and maintained.

Designed for tight spaces and challenging installations, LPC Remotes provide critical insight into water quality while integrating easily into your facility’s overall monitoring setup. These counters support ultra‑fine detection down to 0.1 µm particle size and feature a 100 mL/min flow rate (for most models). They provide dual data channels, 4‑20 mA or Modbus output, and a rugged stainless‑steel enclosure — all designed for reliable operation and seamless connection to facility monitoring systems.

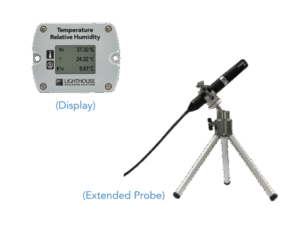

ApexR seamlessly integrates into existing facility monitoring systems (FMS) or building automation systems (BAS) for real-time data streaming, enabling prompt responses to any deviations from set parameters.

ApexR is ideal for monitoring cleanrooms from ISO Class 1 to 8, making it suitable for a wide range of industries. Detecting particles as small as 0.2 microns (depending on model), it provides comprehensive air quality monitoring.

Effortlessly and securely store up to 3,000 particle count records. ApexR provides real-time continuous data collection at a cost-effective price per point, ensuring unmatched performance, accuracy, and reliability.

Housed in a 304 stainless steel enclosure and compatible with rigorous decontamination methods—including vaporized hydrogen peroxide (VHP) sterilization—the ApexR is ready for the most demanding environments.

| Minimum Size | 0.1 µm |

|---|---|

| Channel Sizes | 0.1 µm | 0.2 µm |

| Concentration Limit | 64,000 counts/ml @ 5% coincidence error |

| Data Storage | 2,000 records (modbus models) |

| Flow Rate | 100 mL / minute |

| Dimensions | 5.7”(l) x 5.2”(w) x 3.0”(h) |

| Weight | 3.5 lbs (1.58 kg) |

| Minimum Size | 0.2 µm |

|---|---|

| Channel Sizes | 0.2 µm | 0.3 µm |

| Concentration Limit | 4,000 counts/ml @ 5% coincidence error |

| Data Storage | 2,000 records (modbus models) |

| Flow Rate | 100 mL / minute |

| Dimensions | 5.7”(l) x 5.2”(w) x 3.0”(h) |

| Weight | 3.5 lbs (1.58 kg) |

| Minimum Size | 0.3 µm |

|---|---|

| Channel Sizes | 0.3 µm | 0.5 µm |

| Concentration Limit | 4,000 counts/ml @ 5% coincidence error |

| Data Storage | 2,000 records (modbus models) |

| Flow Rate | 100 mL / minute |

| Dimensions | 5.7”(l) x 5.2”(w) x 3.0”(h) |

| Weight | 3.5 lbs (1.58 kg) |

| Minimum Size | 0.5 µm |

|---|---|

| Channel Sizes | 0.5 µm | 1.0 µm |

| Concentration Limit | 4,000 counts/ml @ 5% coincidence error |

| Data Storage | 2,000 records (modbus models) |

| Flow Rate | 100 mL / minute |

| Dimensions | 5.7”(l) x 5.2”(w) x 3.0”(h) |

| Weight | 3.5 lbs (1.58 kg) |

| Minimum Size | 1.0 µm |

|---|---|

| Channel Sizes | 1.0, 5.0, 10.0, 15.0, 20.0, 25.0, 50.0, 200.0 µm |

| Concentration Limit | 50,000 counts/ml @ 5% coincidence error |

| Data Storage | 1,000 records |

| Flow Rate | 30 mL / minute |

| Dimensions | 9.75”(l) x 3.75”(w) x 3.80”(h) |

| Weight | 4.30 lbs (1.95 kg) |

Contaminants in argon can affect its inertness, leading to unwanted reactions in processes where argon is used to create a stable, non-reactive environment. This is crucial in applications like shielding gases in welding or inert atmospheres in metal manufacturing.

Due to its small atomic size, helium is highly sensitive to particle contamination. Contaminants can affect its efficacy as a cooling medium in cryogenics and its purity in gas chromatography, impacting the accuracy and efficiency of these processes.

Particle contaminants in CO2 can affect its properties as a supercritical fluid, impacting its use in extraction and cleaning processes. In applications where CO2 is used for carbonation or as a refrigerant, purity is essential for both product quality and process efficiency.

Nitrogen is often used for creating inert atmospheres in various industries. Particle contaminants in nitrogen can introduce impurities into these processes, affecting everything from the quality of pharmaceutical products to the integrity of electronic components in semiconductors

In semiconductor manufacturing, impurities in ammonia can lead to defects in nitride films, affecting the performance of electronic devices. In chemical synthesis, contaminants can alter reaction pathways, leading to undesired products or yields.

Other Inert Gases Inert gases like neon, xenon, and krypton are used in specialized applications where their specific properties are crucial. Particle contaminants can alter these properties, thereby affecting the performance in applications like lighting, imaging, or as carrier gases.

We’ve got the answers.

The Mass Concentration Mode approximates particle density in μg/m3, providing valuable data for indoor air quality assessments.

Yes, these devices can function as mobile monitors or be incorporated into comprehensive facility monitoring and management systems.

The counters offer historical data review, password protection, and compatibility with LMS XChange Data Transfer Software and LMS Express for advanced data management.

They are designed for ISO 21501-4 compliance, ensuring unit-to-unit accuracy and repeatability in measurements.

The devices feature removable rechargeable Li-Ion batteries and offer an optional charger to maximize uptime during prolonged monitoring sessions.

LPC Remotes … precision, reliability, and a team who always has your back. You’re not just getting equipment; you’re teaming up with folks who care about your cleanroom’s success.

Please provide your information below, and someone from our team will be in contact shortly.