Solair can do it all! Besides being the best portable in the market, the Solair can be connected to a manifold and used in a real-time monitoring system. Solair incorporates our extreme life laser diode technology sensor to produce the industry’s longest laser diode life of 20+ year MTTF (based on continuous 24/7 operation)

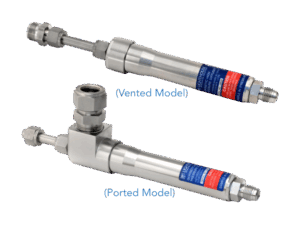

Add a ScanAir Pro filter scanning probe and do filter integrity testing. High pressure diffusers allow you to do particle testing in ultra-pure gasses. Integrate environmental sensors and you have the world’s most versatile portable particle counter.

The Solair Series empowers you to trust every measurement. Designed for accuracy and stability, it delivers simultaneous particle data across multiple size channels, providing a clear and dependable view of your cleanroom environment. With industry-leading sensitivity and reliability, Solair ensures you’re always counting with confidence.

Solair can count and report simultaneously for up to eight different particle size ranges. Practically, this gives you a richer picture of your particle size distribution in one single sampling.

Capable of airborne particle monitoring, gas sampling, filter test challenges, and Solair is also compatible with our environmental sensors - A truly useful cleanroom companion.

Effortlessly and securely store up to 3,000 particle count records across four channels, with a flexible database ready to handle up to 50 custom sampling and report recipes... all at your fingertips when you need them.

Seamlessly transfer your particle count data to USB drives, computers, or monitoring and automation systems using RS‑485 Modbus, USB, Modbus/TCP/IP, printer, web server, or your favorite third-party software.

| Minimum Size | 0.1 µm |

|---|---|

| Channel Sizes | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.5 | 0.7 | 1.0 µm |

| Additional Available | 5.0 µm |

| Flow Rate | 1 CFM (28.3 LPM), 1/4” inlet barb |

| Air Sample Output | Internally Filtered To HEPA Standard (>99.97% @ 0.3µm) |

| Calibration / Compliance | ISO 21501-4 Compliant and accredited ISO 17025 |

| Concentration Limit | 1,000,000 Particles/ft3@10%(35,300,000/m3) coincidence loss |

| Weight | 23.35 lbs (10.6 kg) |

| Minimum Size | 0.3 µm |

|---|---|

| Channel Sizes | 0.3 | 0.5 | 1.0 | 3.0 | 5.0 | 10.0 µm |

| Additional Available | 0.7 | 25.0 µm |

| Flow Rate | 1 CFM (28.3 LPM), 1/4” inlet barb |

| Air Sample Output | Internally Filtered To HEPA Standard (>99.97% @ 0.3µm) |

| Calibration / Compliance | ISO 21501-4 Compliant and accredited ISO 17025 |

| Concentration Limit | 1,000,000 Particles/ft3@10%(35,300,000/m3) coincidence loss |

| Weight | 13.95 lbs (6.33 kg) |

| Minimum Size | 0.5 µm |

|---|---|

| Channel Sizes | 0.5 | 0.7 | 1.0 | 3.0 | 5.0 | 10.0 µm |

| Additional Available | 25.0 µm |

| Flow Rate | 1 CFM (28.3 LPM), 1/4” inlet barb |

| Air Sample Output | Internally Filtered To HEPA Standard (>99.97% @ 0.3µm) |

| Calibration / Compliance | ISO 21501-4 Compliant and accredited ISO 17025 |

| Concentration Limit | 1,000,000 Particles/ft3@10%(35,300,000/m3) coincidence loss |

| Weight | 13.95 lbs (6.33 kg) |

| Minimum Size | 5.0 µm |

|---|---|

| Channel Sizes | 5.0 | 10.0 | 25.0 | 40.0 | 50.0 | 100.0 µm |

| Additional Available | 0.5 | 1.0 | 20.0 | 30.0 µm |

| Flow Rate | 1 CFM (28.3 LPM), 1/4” inlet barb |

| Air Sample Output | Internally Filtered To HEPA Standard (>99.97% @ 0.3µm) |

| Calibration / Compliance | ISO 21501-4 Compliant and accredited ISO 17025 |

| Concentration Limit | 1,000,000 Particles/ft3@10%(35,300,000/m3) coincidence loss |

| Weight | 13.95 lbs (6.33 kg) |

| Minimum Size | 0.3 µm |

|---|---|

| Channel Sizes | 0.3 | 0.5 | 1.0 | 3.0 | 5.0 | 10.0 µm |

| Additional Available | 0.7 | 25.0 µm |

| Flow Rate | 3.5 CFM (100 LPM), 3/8” Inlet Barb |

| Air Sample Output | Internally Filtered To HEPA Standard (>99.97% @ 0.3µm) |

| Calibration / Compliance | ISO 21501-4 Compliant and accredited ISO 17025 |

| Concentration Limit | 400,000 Particles/ft3@10%(14,120,000/m3) coincidence loss |

| Weight | 25.83 lbs (11.73 kg) |

Contaminants in argon can affect its inertness, leading to unwanted reactions in processes where argon is used to create a stable, non-reactive environment. This is crucial in applications like shielding gases in welding or inert atmospheres in metal manufacturing.

Due to its small atomic size, helium is highly sensitive to particle contamination. Contaminants can affect its efficacy as a cooling medium in cryogenics and its purity in gas chromatography, impacting the accuracy and efficiency of these processes.

Particle contaminants in CO2 can affect its properties as a supercritical fluid, impacting its use in extraction and cleaning processes. In applications where CO2 is used for carbonation or as a refrigerant, purity is essential for both product quality and process efficiency.

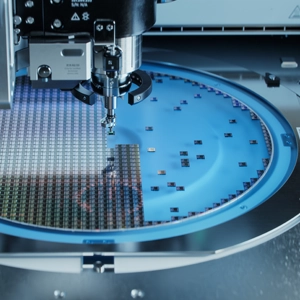

Nitrogen is often used for creating inert atmospheres in various industries. Particle contaminants in nitrogen can introduce impurities into these processes, affecting everything from the quality of pharmaceutical products to the integrity of electronic components in semiconductors

In semiconductor manufacturing, impurities in ammonia can lead to defects in nitride films, affecting the performance of electronic devices. In chemical synthesis, contaminants can alter reaction pathways, leading to undesired products or yields.

Other Inert Gases Inert gases like neon, xenon, and krypton are used in specialized applications where their specific properties are crucial. Particle contaminants can alter these properties, thereby affecting the performance in applications like lighting, imaging, or as carrier gases.

We’ve got the answers.

ApexP offers monitoring of particles in the air and most inert gases (with an optional High Pressure Diffuser).

ApexP3 detects particles from 0.3–10.0 μm

(channels at 0.3μm, 0.5μm, 1.0μm, and 5.0μm).

ApexP5 covers 0.5–10.0 μm

(channels at 0.5μm and 5.0μm).

Both models have a flow rate of 1.0 CFM (28.3 LPM).

ApexP utilizes internal self-diagnostics that continuously monitor the health of the laser, flow rate, and particle detector to ensure the instrument is operating within specified tolerances. This supports reliable and accurate measurement for cleanroom data.

The instrument can securely store up to 3,000 records of particle count data from up to four channels and up to 50 sampling/reports “recipes.”

It supports data transfer via USB, RS‑485 Modbus, Modbus/TCP/IP, printer, web server, or third-party software for seamless integration with monitoring and automation systems.

Yes! With the optional High Pressure Diffuser accessory, the ApexP becomes suitable for most inert gases, including:

This makes it versatile for many gas monitoring applications.

ApexP is compact and lightweight, offering VHP compatibility, intelligent self-diagnostics, a bright touchscreen interface, secure remote access, high data integrity, and wide compatibility with cleanroom and industrial gas applications—all in the smallest portable package available.

Solair … precision, reliability, and a team who always has your back. You’re not just getting equipment; you’re teaming up with folks who care about your cleanroom’s success.

Please provide your information below, and someone from our team will be in contact shortly.