Meet ApexZ: your ultimate partner in maintaining pristine cleanroom environments. This state-of-the-art airborne particle counter goes beyond simply measuring particles, giving you the confidence to manage your critical spaces with both precision and ease.

With its advanced laser technology, intuitive 7-inch touchscreen, and rugged, chemically resistant enclosure, ApexZ delivers reliable results in even the most demanding settings. You’ll move smoothly through your workflow thanks to features like hot-swappable batteries, flexible data views, and built-in compliance tools.

We know every facility is different, so ApexZ lets you customize your sample settings to match your established SOPs.

Set up groups, presets, sample plans, and certifications to automate your routine and cut down on repetitive work. This way, you’re always sampling the right locations with the right parameters, every time.

With an optional barcode scanner, ApexZ lets you quickly identify locations or batches, while customizable data tags (up to five per sample) let you track everything from batch numbers to room status. This makes it easy to filter and find the data you need later, and helps keep your records clean and organized.

Download the DatasheetYour data is only as good as your records. So ApexZ supports 21 CFR Part 11 compliance, with audit trails that log every action, user, and timestamp. You get multiple user and security levels, so only authorized folks can make changes. With storage for up to 10,000 samples, 2,500 locations, and 20,000 audit trail records, you’ll never have to worry about running out of space or losing track of what happened when.

Sampling should be simple, not stressful. The 7-inch multi-touch display puts all your data front and center, and the grid view makes it a breeze to see which locations have been sampled and which are up next. Color-coded indicators—green for done, blue for sampling, grey for to-do, orange for warnings, and red for alarms — help you keep track at a glance and avoid missed spots.

Learn about Going PaperlessAt just over 7 pounds and with a compact footprint, ApexZ is easy to carry from room to room. It’s the smallest, lightest, and quietest portable particle counter out there, so you can move fast without making a scene or breaking your back.

No need to hover over the unit — just glance at the handle. Integrated status lights give you a 360-degree view of what’s happening, even from across the room. You’ll know instantly if everything’s running smoothly or if something needs your attention.

And you can forget about being tethered to a wall outlet. ApexZ comes with hot-swappable smart batteries that can run for up to 11 hours straight. Need more juice? Just pop in a fresh battery — no need to stop sampling. And if you’re in a rush, you can charge up to 80% in just 90 minutes. You can even run the unit on a single battery while charging the other externally, so you’re never left waiting around.

Implement Your Own EM SystemApexZ isn’t just another particle counter — it’s built to keep you confident in your results day in and day out. Its self-diagnostics system is always running in the background, checking the laser’s power, current, and supply, as well as monitoring airflow and sensor health. If anything’s off, you’ll know right away, long before it could impact your data. This means less downtime, fewer surprises, and more trust in your cleanroom monitoring.

We know that cleanrooms are tough on equipment, but ApexZ is tougher. Its sealed enclosure is rated IP54 and is chemically compatible with all the main disinfectants – including VHP, so you can wipe it down as often as you need without worrying about damage. The rotating exhaust nozzle keeps things flexible, and the whole unit is built to handle the demands of pharmaceutical, semiconductor, and other high-stakes industries.

Learn about Systems

| Compliance | ISO 14644, ISO 21501-4, and 21 CFR Part 11 compliance for environmental and cleanroom monitoring. Suitable for GMP air monitoring. |

|---|---|

| Customization | Eight selectable particle size channels |

| Detection | Detect airborne particles as small as 0.3 µm |

| Alarms | RGB lighted handle status indicator, plus user-configurable warnings and alarms |

| Battery | 2x Li-Ion battery slot capacity, removable/rechargeable, up to 11 hours nominal use |

| Data Output | Bi-Directional integration into LIMS EM system |

| Diagnostics | Advanced self-diagnostics |

| Enclosure | VHP compatible sensor and housing |

| Compliance |

ISO 14644, ISO 21501-4, and 21 CFR Part 11 compliance for environmental and cleanroom monitoring. |

|---|---|

| Customization | Six selectable particle size channels |

| Detection | Detect airborne particles as small as 0.5 µm |

| Alarms | RGB lighted handle status indicator, plus user-configurable warnings and alarms |

| Battery | 2x Li-Ion battery slot capacity, removable/rechargeable, up to 11 hours nominal use |

| Data Output | Bi-Directional integration into LIMS EM system |

| Diagnostics | Advanced self-diagnostics |

| Enclosure | VHP compatible sensor and housing |

| Minimum Size | 0.3µm |

|---|---|

| Channel Sizes | 0.3 | 0.5 | 1.0 | 3.0 | 5.0 | 10.0µm |

| Flow Rate | 1 CFM (28.3 LPM) |

| Sample Inlet | 3/8" Inlet Barb |

| Concentration Limits | 1,000,000 Particles/ft3 @10% (35,300,000/m3) Coincidence loss suitable for ISO classes 1-8cleanrooms |

| Air Sample Output |

Internally Filtered To HEPA Standard (>99.97% @ 0.3µm) |

| Dimensions | 12.76“ (l) x 6.23” (w) x 8.88” (h) |

| Weight | 7.05 lbs (3.19 kg) without batteries, battery weight 1.35 lbs (0.61 kg) |

| Minimum Size | 0.5µm |

|---|---|

| Channel Sizes | 0.5 | 0.7 | 1.0 | 3.0 | 5.0 | 10.0µm |

| Flow Rate | 100 LPM (3.5 CFM) |

| Sample Inlet | 1/2" Inlet Barb |

| Concentration Limits | 300,000 Particles/ft3 @10% (10,590,000/m3) Coincidence loss suitable for ISO classes 1-8 cleanrooms |

| Air Sample Output |

Internally Filtered To HEPA Standard (>99.97% @ 0.3µm) |

| Dimensions | 12.76“ (l) x 6.23” (w) x 8.88” (h) |

| Weight | 7.05 lbs (3.19 kg) without batteries, battery weight 1.35 lbs (0.61 kg) |

For additional technical specifications, please see the product datasheet.

Contaminants in argon can affect its inertness, leading to unwanted reactions in processes where argon is used to create a stable, non-reactive environment. This is crucial in applications like shielding gases in welding or inert atmospheres in metal manufacturing.

Due to its small atomic size, helium is highly sensitive to particle contamination. Contaminants can affect its efficacy as a cooling medium in cryogenics and its purity in gas chromatography, impacting the accuracy and efficiency of these processes.

Particle contaminants in CO2 can affect its properties as a supercritical fluid, impacting its use in extraction and cleaning processes. In applications where CO2 is used for carbonation or as a refrigerant, purity is essential for both product quality and process efficiency.

Nitrogen is often used for creating inert atmospheres in various industries. Particle contaminants in nitrogen can introduce impurities into these processes, affecting everything from the quality of pharmaceutical products to the integrity of electronic components in semiconductors

In semiconductor manufacturing, impurities in ammonia can lead to defects in nitride films, affecting the performance of electronic devices. In chemical synthesis, contaminants can alter reaction pathways, leading to undesired products or yields.

Other Inert Gases Inert gases like neon, xenon, and krypton are used in specialized applications where their specific properties are crucial. Particle contaminants can alter these properties, thereby affecting the performance in applications like lighting, imaging, or as carrier gases.

We’ve got the answers.

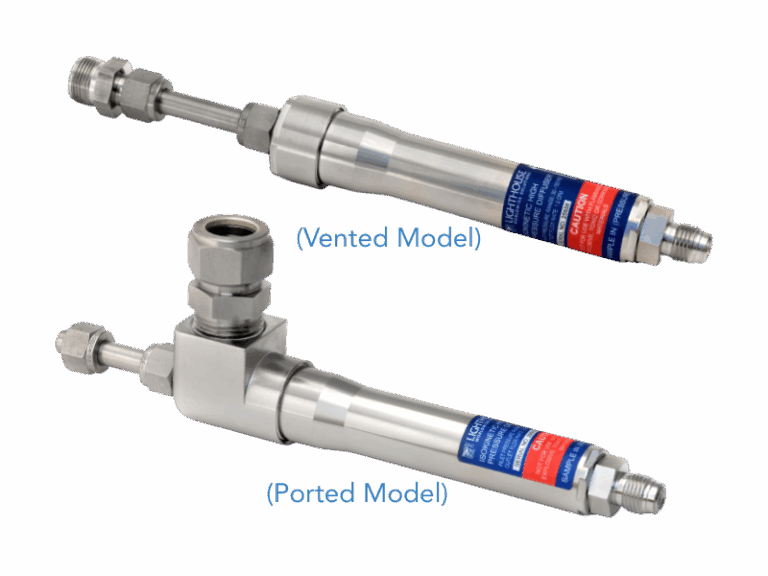

Both models offer six standard particle size channels and are suitable for ISO Class 1-8 cleanrooms.

ApexZ features an intuitive interface, automated reporting, and customizable sample settings that streamline workflows and ensure audit readiness. Its self-diagnostics, wireless networking, and bi-directional integration with LIMS EM systems enable seamless data management and compliance with regulatory requirements.

ApexZ can be configured remotely using LMS XChange software, allowing users to set up and clone instrument settings across a fleet via WiFi, Ethernet, or USB. This makes fleet management and expansion simple and efficient.

ApexZ is designed for versatility and user-centric operation, making it suitable for a wide range of industries including pharmaceuticals, semiconductors, automotive, and food packaging. Its robust design and advanced features ensure it can adapt to various cleanroom and controlled environment needs. For personalized recommendations, Lighthouse offers consultations to determine the best fit for your requirements.

ApexZ makes cleanroom monitoring simple, bringing all your data and controls together on an intuitive touchscreen so you can quickly view, filter, and export reports in your preferred format without any hassle. Thanks to its smart battery management and rugged, portable build, you can move from room to room seamlessly, never missing a beat. With customizable user permissions and easy network integration, your workflow stays secure and efficient, letting you focus on what matters most.

Experience just how easy and stress-free particle monitoring can be with ApexZ — reach out and see for yourself.

Please provide your information below, and someone from our team will be in contact shortly.